3rd generations Automatic Hoof Wash system for AMS

NEW Bovibooster

The Bovibooster MK5 is our third generation of our system developed for hoof wash and disinfection in automatic milking robots. The system is powered by compressed air, directly from the milking robot compressor. The main unit is available as a single version for one milking robot, and a double version for two milking robots, placed next to each other.

- Automatisk vaskesystem

- Forebyggelse og behandling

Reservedele og tilkøb fås i shoppen eller hos din forhandler

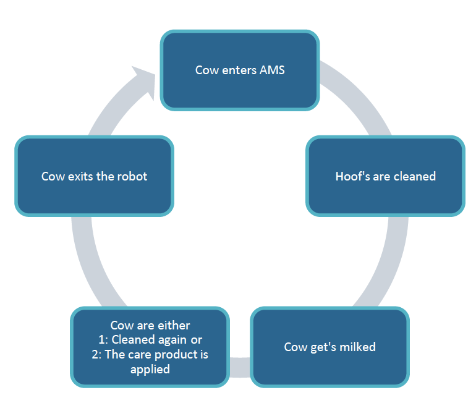

Sådan virker Bovibooster

Bovibooster består af:

Main/Wash unit

The Bovibooster main unit includes the electrical control box, the PS1250 pneumatic wash pump andthe PD2.5 detergent injection pump. Detergent concentration is adjustable from 0-0,8% with a 0,2%interval. Every wash cycle has a fixed volume of 1250 ml sprayed with 9-12 bars of pressure. Thesystem can be set to wash at both cow entry and cow exit

Care pump

The PD15 is self-priming reciprocating pneumatic pump for disinfection. Each spray delivers 15 ml intotal, through two spray nozzles, just before the cow leaves the robot.

Start signal box

The start signal terminal box connects the Robot start signals, the PD15 and the disinfectant levelsensor to the Bovibooster main unit. Start signals can be pneumatic or electric (normally opencontact).

Spray bar

The Bovibooster spray bar is special designed for the robot. It consist of four adjustable nozzles, twofor wash and two for disinfection.

Forbrug

Pr. påfyldning

Water: 1250 ml.

Soap: 2,5-10ml. (concentrated)

Care: 15 ml. (premixed)

Årligt forbrug

Pr. robot på standard program

Air: 170 Kwh/year

Water: 81,25 m3

Soap: 162,5 l (concentrated)

Care: 450 l (premixed)

Hvorfor Bovibooster?

Nem betjening

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna

Effektiv klovvask

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna

Flytbar

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna

Tekniske specifikationer

Main/Wash unit

Care pump

GEA R9500 Spray bar

Start signal terminal box

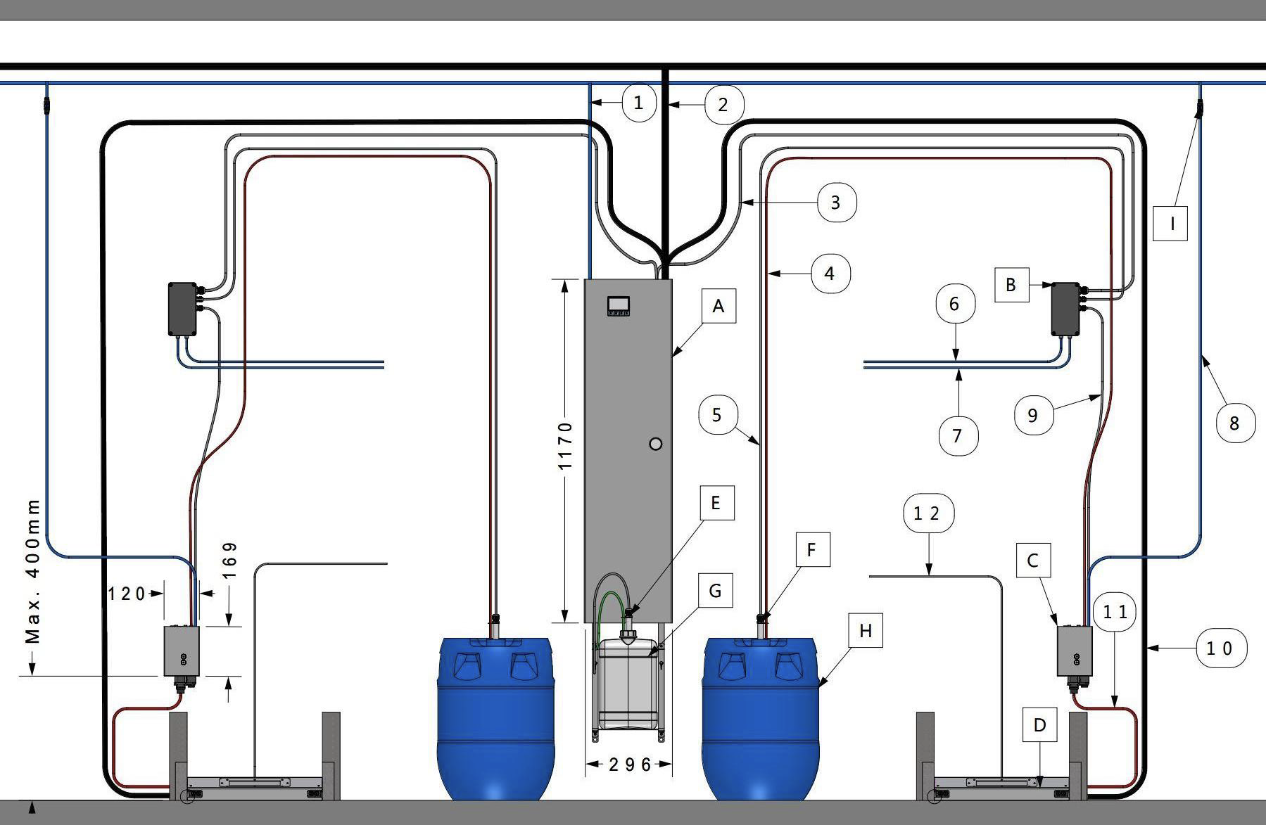

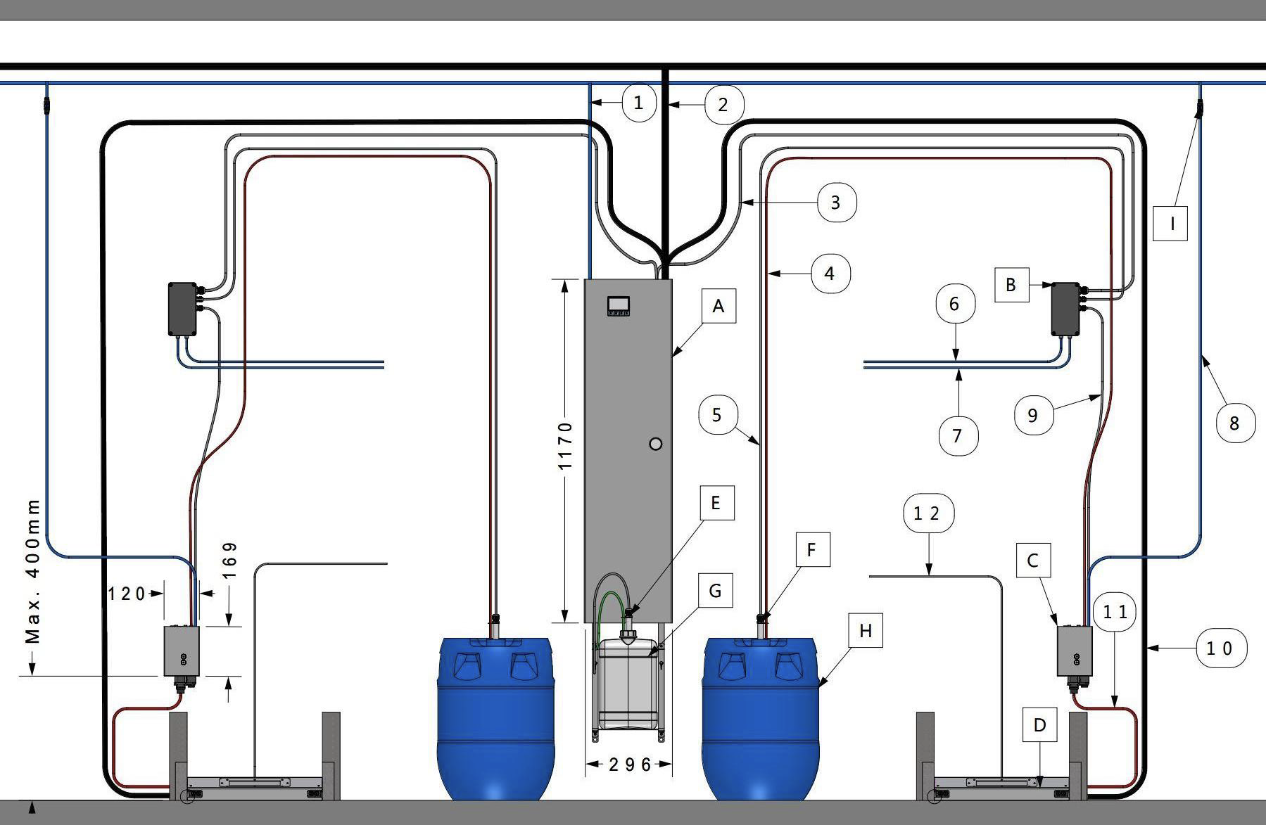

Installations komponenter og dimensioner

BStart signal terminal box

CPD15 care pump

DGEA R9500 Spray bar

EDetergent level sensor suction lance

FDisinfectant level sensor suction lance

GDetergent container 10 or 25 kg with bracket

HDisinfectant container 20-200 L

IPD15 air supply exhaust valve

2Water supply:13/19 mm tube

3Start signal box:7×0.75mm2 numbered control cable

4Suction tube PD15:6/4 mm tube

5Level sensor:2X0.75mm2 numbered control cable

6Start signal entrance:4/2 mm tube or 2X0.75mm2 numbered control cable

7Start signal exit:4/2 mm tube or 2X0.75mm2 numbered control cable

8Air supply PD15:8/6 mm tube

9PD15 control cable:3×0.75mm2 numbered control cable

10Wash spray tube:16/13 mm tube

11Disinfection spray tube:8/6 mm tube

1224 Vdc LED bar:2×0.50mm2

Kompatibel med

Officiel tredjepart leverandør hos Lely

Bovi Hoof Care are official third part supplier of the Meteor system to Lely Industries. We have through a close partnership with Lely Industries created the Meteor concept. This concept is the all-round approach for optimal hoof health. With farm management to create the right environment, and then the 2 phases: corrective hoof care and preventive hoof care.

Kontakt os

Vi er altid klar til at besvare dine spørgsmål eller have en snak om klovpleje.

Hvis du ønsker at blive en del af Bovi-familien, så tøv ikke med at kontakte os.